- General Description

- Application feacture

- Specification

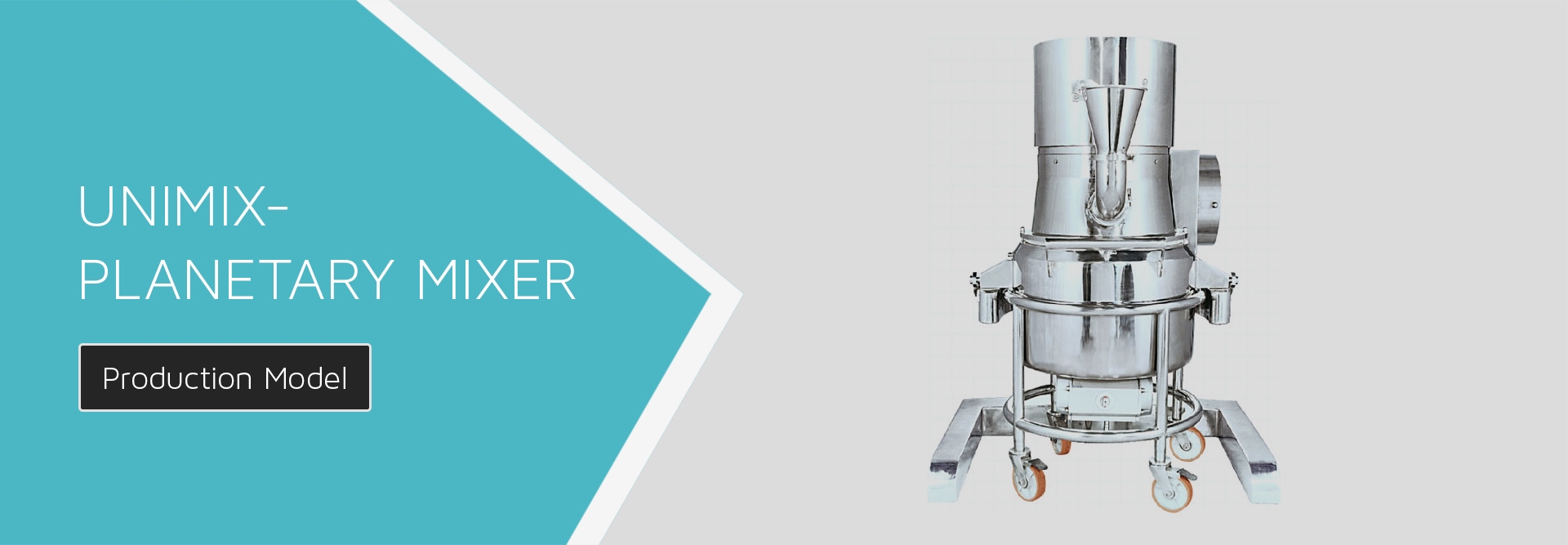

- All contact parts of the mixing bowl and beater are made out of S.S 316. Scrapping bladers can also be provided if required.

- The mixing bowl can be jacketed for electric/ steam/thermic fluid heating.

- Ideal equipment for small batch sizes.

- Manual lifting arrangement for agitator up to 50 lits and motorized lifting arrangements for capacities of 100 litters and above can be provided.

- The top of the mixing bowl has an S.S. lid with a charging hole.

- The mixing bowl is provided with castor wheels and locking system for easy handling and transportation.

- VSHSE option can be provided.

- Powder to powder mixing

- Dry powder to wet paste for wet granulation.

Manufacturer and Supplier of Mixing Machines

Planetary mixer

In powder two different dimensions in the mixing process can be determined: convective mixing and intensive mixing In the case of convective mixing material in the mixer is transported from one location to another. This type of mixing leads to a less ordered state inside the mixer, the components that must be mixed are distributed over the other components. With progressing time the mixture becomes more randomly ordered. After a certain mixing time the ultimate random state is reached. Usually this type of mixing is applied for free-flowing and coarse materials. Possible threat during macro mixing is the de-mixing of the components, since differences in size, shape or density of the different particles can lead to segregation.

General Description:

Application feactures:

Specification :

| Model No | Dry Capacity (kg) | Total Capacity (kg) | Motor (hp) |

| UNIPLM- LAB | |||

| UNIPLM-10 | 1 | 2 | 1 |

| UNIPLM-20 | 2 | 4 | 1.5 |

| UNIPLM-30 | 3 | 6 | 2 |

| UNIPLM-50 | 8 | 16 | 3 |

| UNIPLM-90 | 15 | 30 | 5 |

| UNIPLM-140 | 25 | 50 | 7.5 |

Contact us for more information on Supply and Manufacturing of Planetary mixer or to discuss your requirements. Email us at sales@sbpanchal.com / hiren@sbpanchal.com