- Description

- Optional Features

- Applications

- Specification

- Option of 21cfr part 11 compliance control system.

- Explosion Isolation valve.

- Quick acting safety valves for isolation

- Vaccuum transfer system for loading and unloading

- Pharmaceutical Formulation and Bulk drugs Eg. Sustain Release, Enteric Release Coating on tablets.

- Organic and Inorganic chemicals

- Agrochemicals and fertilizers.

- Nutraceuticals and Biotech Products

- Speciality chemicals

- R & D Institutes and colleges

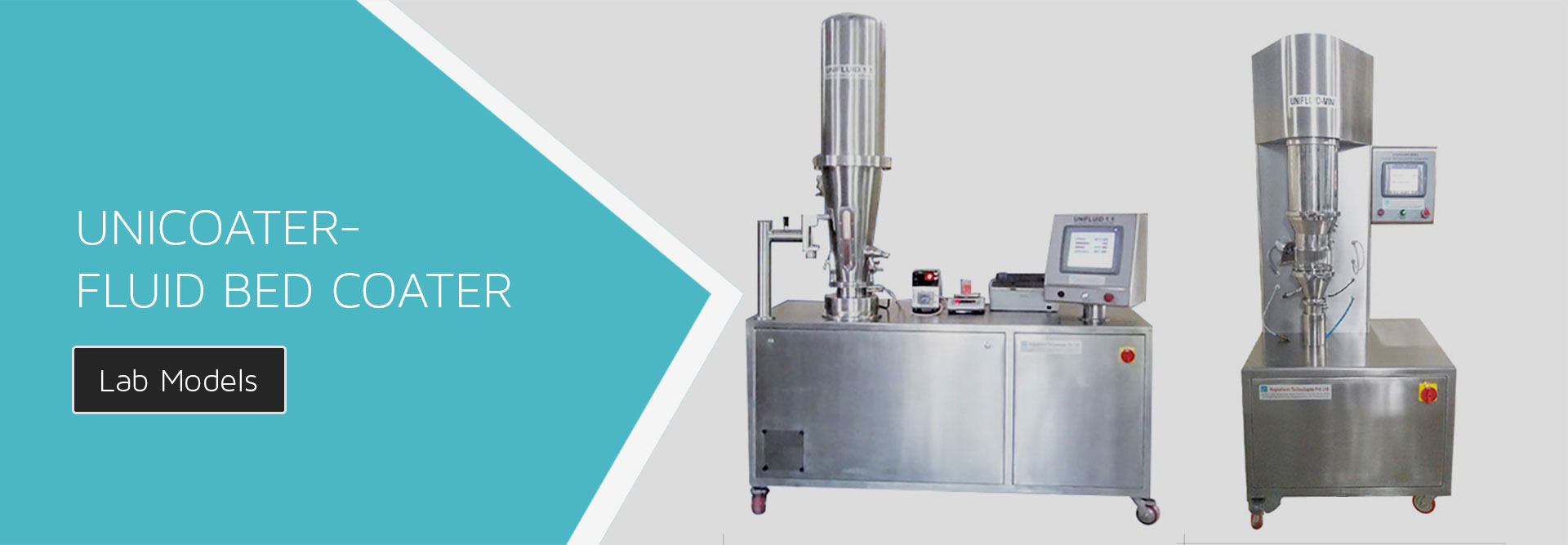

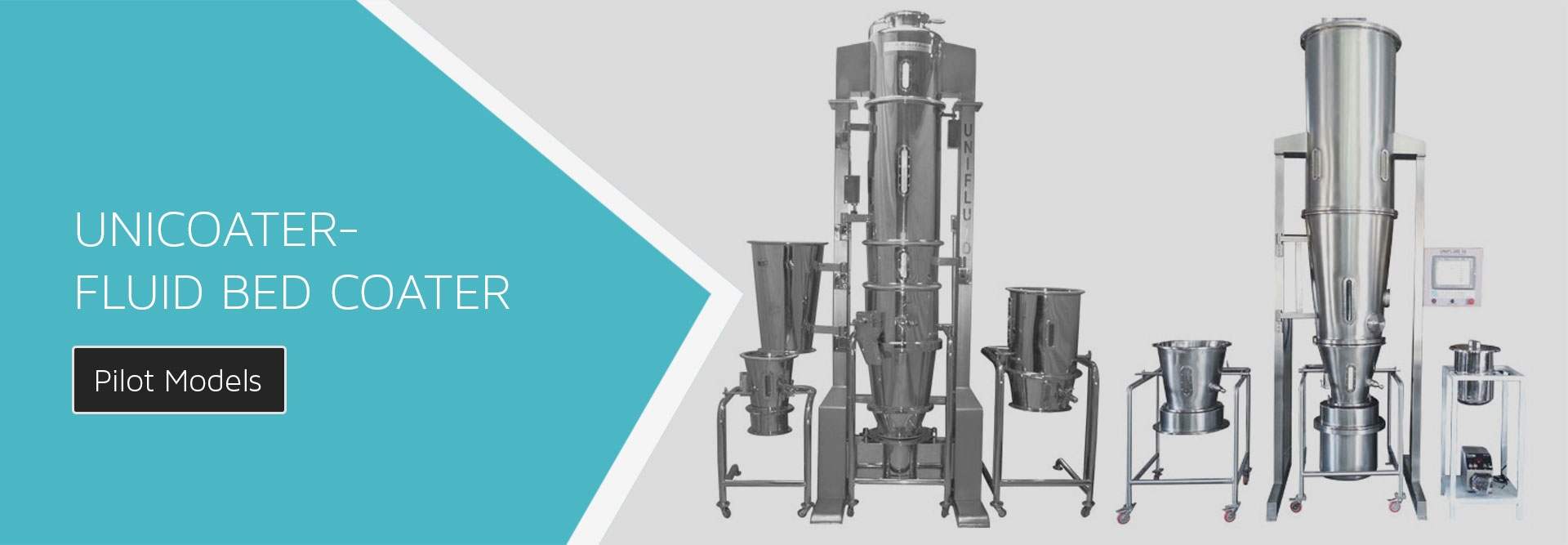

Manufacturer and Supplier of Fluid Bed Coater

S.B. Panchal & Co. manufactures full range of Fluid Bed Processing systems ranging from contemporary Fluid Bed Dryers to state of the art Fluidized Bed Coating and Granulating Systems.

General Description :

Wurster Coaters applies to a smaller range of pellets. This type of coating method is frequently used for applications in which a large amount of coating or drug layer is applied to a substrate. A special designed partition is made for coating very fine, cohesive powder. Wurster fluid bed coating processcan provide a film coat of the highest quality and uniformity compared to other techniques. This uniformity can minimize coating thickness requirements, further reducing the amount of coating materials needed and the processing time. The Wurster coating process can be applied to a range of core materials in numerous particle sizes and shapes. The process is flexible enough to coat small particles for use in capsules and tablets, as well as coating the full capsules and tablets. Coating capabilities extend all the way to coating soft gels capsules, extruded materials, powders, crystals and granules. No matter the shape—spherical, crystalline, irregular, amorphous—the Wurster process is capable of creating a unique formulation to achieve the desired properties.Optional Features :

Applications :

Specification :

| MODEL | Unifluid Mini | Unifluid 1.1 | Unifluid 3.1 | Unifluid 5 | Unifluid 10 | Unifluid 30 | Unifluid 60 | Unifluid 120 | Unifluid 200 | Unifluid 300 | Unifluid 500 |

| Capacity in Kgs at 0.6 gm/cc Bulk Density | 50 gm-200 gm | 300gm-1kg | 1kg-3 kg | 1 kg – 5 kg | 3kg-10kg | 30 | 60 | 100 | 200 | 300 | 500 |

| Total Volume of Product Capacity in Litres |

500ml | 5 | 15 | 22 | 45 | 125 | 250 | 500 | 800 | 1100 | 1300 |

| Compressed Air required in CFM | 3 |

6 | 9 | 15 | 25 | 30 | 30 | 30 | 95 | 95 | 200 |

| Heating Load in K.W. | 2 | 4.5 | 6 | 9 | 12 | NA | NA | NA | NA | NA | NA |

| Blower Motor H.P.* | 0.5 | 1 | 3 | 5 | 10 | 20 | 30 | 40 | 50 | 60 | 75 |

Contact us for more information on Supply and Manufacturing of Fluid Bed Coater or to discuss your requirements. Email us at sales@sbpanchal.com / hiren@sbpanchal.com