- General Description

- Optional Features

- Specification

- Intermediate Bulk Containers (IBC’s)

- Paste Kettle

- Blender

- Integrating Cone Mill

- Automatic Tablet Coater

- Tablets press

- Capsules filling machine

- PLC Control

- CE certified

Manufacturer and Supplier of UNILIFT- Elevators

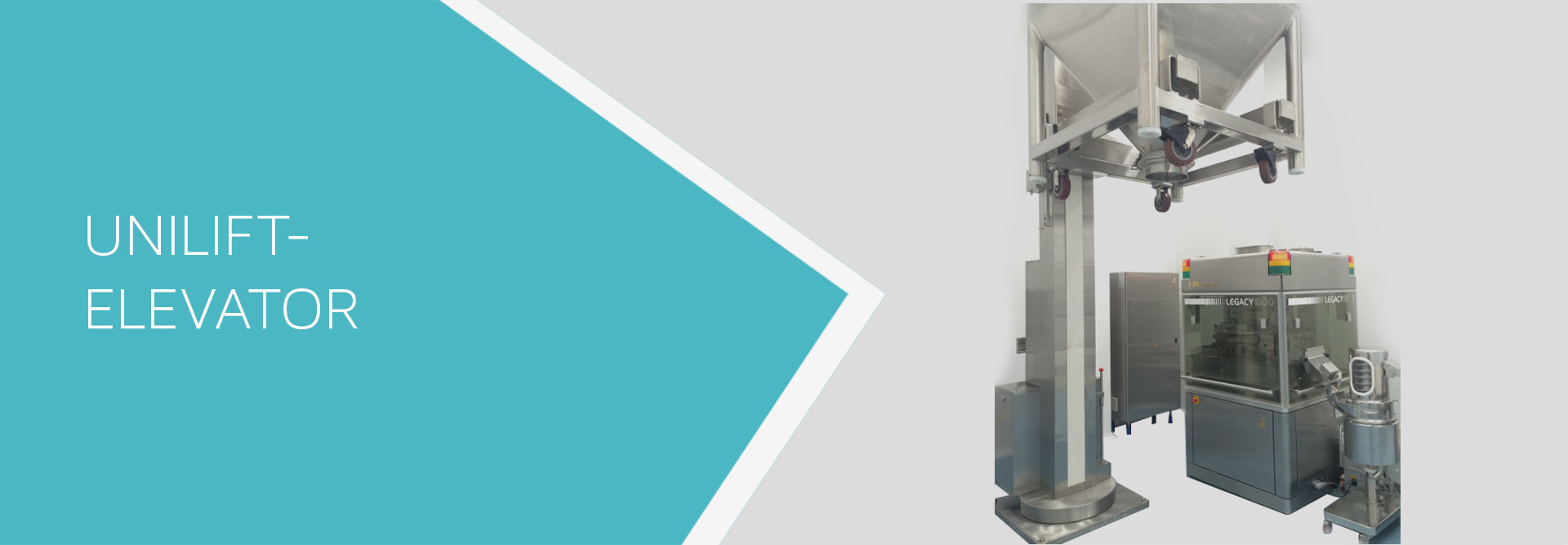

General Description:

This equipment is composed of Fixed Chassis or a Moveable Chassis on Trolley with lifting and valve opening systems. When operating, lock first the Bin with lifting arms, then press “Raise” button to raise the Bin. When it is in raised in position, swivel the container to locate it in position. You can open the valve once container is in position to empty the contents of the Bin.

If inversion of Bin is required Press “Invert” button to invert it 180° and align the Bin to dock to the inlet of the next processing equipment, and then open the butterfly valve to discharge the materials.

Tipper is mainly used in the solid dosage production procedure for transferring and discharging materials, consequently it is operated with corollary equipment such as

Optional Features:

Specification:

| MODEL | Gross Capacity (lit) | Working Capacity (lit) | Length (mm) | Breadth (mm) | Motor (H.P) | Weight (kg) |

| UNILIFT-100 | 100 | 100 | 1100 | 1800 | 1.5 | 600 |

| UNILIFT-300 | 300 | 300 | 1100 | 1800 | 1.5 | 600 |

| UNILIFT-500 | 500 | 500 | 1100 | 2200 | 1.5 | 600 |

| UNILIFT-1000 | 1000 | 1000 | 1100 | 2500 | 1.5 | 600 |

| UNILIFT-1500 | 2000 | 1500 | 1100 | 2800 | 1.5 | 600 |

Contact us for more information on Supply and Manufacturing of UNILIFT- Elevators or to discuss your requirements. Email us at sales@sbpanchal.com / hiren@sbpanchal.com